How To Draw Gear Teeth In Autocad

- TOP >

- Gear Drawing

Gear drawing required for machine design

A gear drawing is a type of important technical reference required when designing machines. When a machine designer requires a gear when designing a new machine, there are two possibilities: designing the new gear itself, and utilizing a standard gear which has already been designed. In either case, the gear drawing is indispensible.

Although this applies to machine elements in general, gear drawings must contain accurate descriptions of principle gear specifications such as number of teeth, pitch such as modules, pitch circle diameter (PCD), helix angle of helical teeth, value of tooth profile shifting, precision grade such as DIN and AGMA, geometrical tolerance, and roughness of surface.

Also, because the strength to allow the torque required to transmit power through the gears is required, it is also necessary to accurately list the hardness of the gear, which is quantified in terms of gear material, tempering or lack thereof and tempering method, HRC and HB achieved after tempering, etc. Gear drawings are generally provided in 2D CAD, 3D CAD, and print media formats, but on the KHK website it is also possible to output a drawing with the modifications applied to stock gears such as bore, keyway, and set screw hole part modifications.

Selectable format (file name extension) of 3D CAD models :

Creo Parametric 3.0/2.0 (.prt), Pro/ENGINEER Wildfire/2001 (.neu), Pro/ENGINEER Neutral (.neu), Autodesk Inventor (.stp), Solidworks (.x_t), Parasolid (.x_t), AutoCAD 3D (.sat), CATIA V5 (.igs), CATIA V4 (.igs), IGES (.igs), STEP (.stp), ANVIL (.stp), CADKey 3D (.stp), IronCAD (.stp), Mechanical Desktop (.stp), 3D PDF (.pdf), ACIS (.sat), SDRC I-DEAS (.stp), Unigraphics (.stp), AutoCAD 2D (.dxf), DXF file (.dxf), eDrawings (R) 2D (.dxf)

How to draw a gear

We offer free gear drawing software. Please CLICK HERE

Gear Drawings

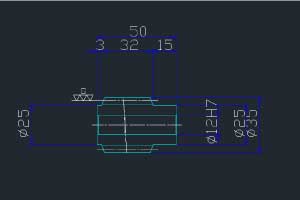

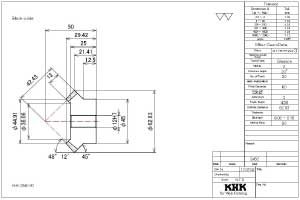

- Items contained in gear drawings Gear drawings show the orthogonal views of the gear and a table of essential data. The orthogonal views indicate detailed shape other than the tooth form, size, geometric tolerances and surface roughness. The surface roughness is to be put on the dashed line of the reference circle of the gear cross section. In addition, if the tooth position or phasing is important for the function of the part, it is indicated by the distance from the center line of the tooth or space between the teeth to the keyway or screw hole, for example.

- Precautions to be observed when drawing gears A gear is not used by itself. Therefore, it is desirable to describe the mating gear's information such as the center distance. Also if the tooth contact is of concern, crowning and end relief, etc. can be specified. For crowning, it is better to specify the curvature in the tooth trace direction.

- Precautions related to tooth forms In the past, it was not necessary to draw tooth forms in gear drawings. However, more recently gears are increasingly made using 3D data with electro-discharging machining or 3D printers. For these cases where the gears are made without the gear cutting tools, it is necessary to accurately draw the gear tooth forms.

In contrast, the tabulated portion shows the gear specifications (size, precision, material, and treatment) as well as span or over pin measurement for the inspection dimension. In other words, the tabulated data determines the performance of the tooth profile and are indispensable for gear drawings.

Related links :

Types of Gears - A detailed description of Types of Gears

Gear Rack and Pinion - A detailed description of Gear Rack and Pinion

Free Gear Drawing Software

齿轮图纸 - 中文页

How To Draw Gear Teeth In Autocad

Source: https://khkgears.net/new/gear_drawing.html

Posted by: coaxumdevens.blogspot.com

0 Response to "How To Draw Gear Teeth In Autocad"

Post a Comment